3 Simple Techniques For Watry Industries

3 Simple Techniques For Watry Industries

Blog Article

What Does Watry Industries Do?

Table of Contents7 Simple Techniques For Watry IndustriesSome Known Details About Watry Industries The 10-Second Trick For Watry IndustriesSome Of Watry IndustriesExcitement About Watry IndustriesWatry Industries for Beginners

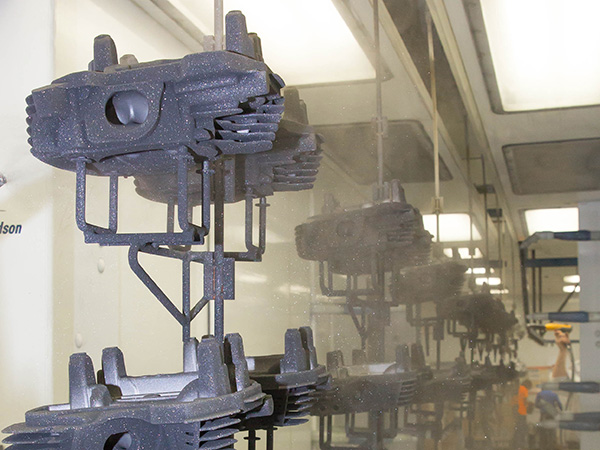

Since power generation is a very capital intensive sector, the series of steel elements with machining is important (aluminum foundry). Fittings for trailer structures, warm exchanges, and covering plates that contain tubular shapes require to be reduced into a specific size and with openings to allow strong attachments. Innovative and innovative machining components are required for water, gas and vapor, and wind power.

The Shop and its staff specialize in study and academic environments, screening fixtures and manufactures of all sizes. Our services are readily available to all divisions in the College of Design in addition to various other colleges and academic departments at the College of South Florida. Design help, repair services, construction and assembly using a wide variety of materials, including steel, stainless-steel, aluminum, plastics and timber Complete enhance of modern-day accuracy tooling and equipment, including CNC (Computer Numerical Controlled) machining making use of FeatureCAM CNC software application that can convert SolidWorks and AutoCAD information to fulfill your layout requires Our shop is completely furnished with different welders including TIG, MIG, Stick welders and a Plasma Cutter Our wood shop uses a wide array of woodworking machinery, equipment and hand devices for milling, exploration and reducing timber and plastic CNC Milling Machines CNC Turret Manual Milling Machines Manual Milling Lathes Surface Grinder Radial Arm Drill Press Vertical Bandsaw Horizontal Bandsaw Cold Saw Unpleasant Cut-Off Saw Oxy-Acetylene Lantern Plasma Cutter TIG Wedler MIG Welder Stick Welder Hand-held Place Welder Shear Bending Brake Beverly Shear Tubing Bender Notcher Drill Press Arbor Press 17.5 Ton Hydraulic Press Barrier Drill Mill Various Handbook and Power Hand Devices.

The Definitive Guide for Watry Industries

((https://papaly.com/categories/share?id=ec07d321d9884e2d9589c8a5ed04d3b1))

Sadler Equipment Co. is an extremely recognized CNC maker shop, work store, maintenance, and proto-type machining business found in the heartland of America, in Cedar Rapids, Iowa.

Machining is an umbrella term that is used to create parts by removing material from a strong work surface. In the past, machining was normally utilized for steels, however today it is likewise utilized for plastics and a variety of other unique products. Machining can consist of drilling, boring, transforming, cutting, milling, knurling and also grinding to develop the certain called for form.

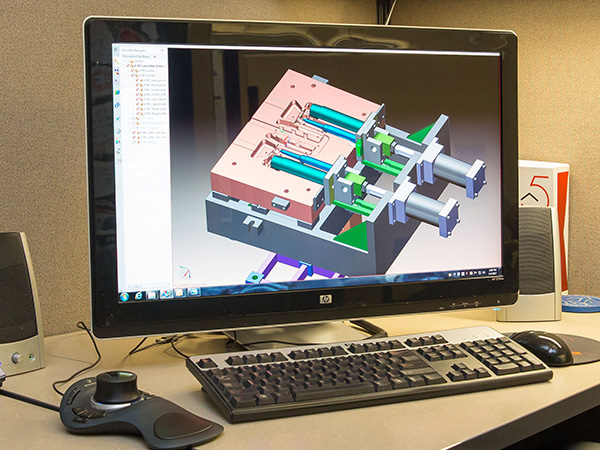

CNC machining is additionally known as Computer system Numerical Control machining, and it uses the accuracy of a computer to regulate the particular maker and tool in the machining process. In this sort of machining, precision is the focus, with the tool and the machine making the exact very same elimination of the material from the workpiece with every unit.

The 6-Minute Rule for Watry Industries

Today's machine shops, however, are really various. Device shops consist of several items of tools, though the array and kind of devices rely on the size and function of the center. Shops commonly have some or every one of the adhering to devices, along with others: Milling maker. A mill is a device that makes use of rotary cutters to eliminate product from the workpiece.

Machining. A machining facility is an additional term utilized to describe a CNC milling maker, a mill managed by computer system guidelines. Machining centers are multifunctional items of devices qualified of executing complex treatments at high manufacturing prices. Lathe. A turret is a kind of machine that rotates a work surface as it reaches a reducing device, making it possible for procedures like sanding, knurling and dealing with.

The Single Strategy To Use For Watry Industries

Grinding machine. A grinding machine is a kind of power tool that makes use of an unpleasant wheel to grind the workpiece. Grinding is usually utilized as a completing process, due to the fact that it gives a high surface area top quality. Pierce press. A drill press is a kind of installed drill whose movement is regulated by a bar.

A bandsaw is a multi-use reducing maker made use of to make straight cuts. Electrical Discaharge Machining (EDM) is a procedure that makes use of sparks rather of a physical reducing tool to penetrate the work surface. Alternate variations of the modern technology use a cord for the device electrode.

Indicators on Watry Industries You Should Know

Makers lug out different manufacturing procedures, and might be either hands-on (run by a machinist) or geared up with Computer Numerical Control (CNC) modern technology. Besides equipment, an equipment shop might also include shops of resources that can be machined to make parts. Depending on the range of the manufacturer, products may be stored somewhere page else, in a warehouse.

Some devices, such as 5-axis CNC mills, have rotating spindles or tables, which enables the cutting tool to reduce the block of product from any angle without disruption. The 5-axis CNC machining modern technology can equipment parts really quickly, which is helpful for machine stores creating huge amounts of components for significant jobs.

3 Easy Facts About Watry Industries Explained

Furthermore, machinists operating at CNC factory are typically skilled in electronic design and therefore capable of customizing digital designs for CNC machining. Mostly all CNC machinists have experience in hand-operated machining, as this ability aids them much better comprehend the CNC machining process. Additionally, a CNC factory will typically be capable of working from electronic CAD data, technical drawings or a combination of both.

Report this page